How To Avoid Problems Caused by Moisture in Sandpaper

In industrial production and daily applications, sandpaper is a common grinding tool, and its quality directly affects the efficiency and effectiveness of work. However, many people may overlook an important factor in the preservation and use of sandpaper – moisture.

What are the effects of moisture on sandpaper? How to prevent sandpaper from getting damp and causing unnecessary losses?

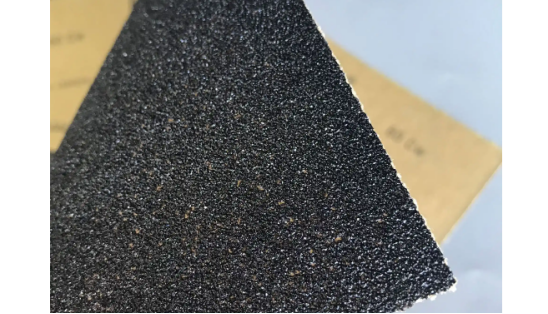

Sandpaper is essentially composed of abrasive particles (such as chromite, alumina, etc.) and adhesive. Under normal dry conditions, the particles and adhesive of sandpaper can maintain stable physical properties, but when sandpaper becomes damp,it may cause the following problems:

- Reduced grinding effect: The surface of damp sandpaper will become uneven due to moisture absorption, resulting in particle detachment or decreased particle adhesion, which reduces grinding efficiency.

- Easy to break or fall off: The damp environment weakens the adhesive of sandpaper, and the adhesive will lose a certain bonding strength after being dampened, which may cause the grinding particles of sandpaper to fall off, and even cause sandpaper to break.

- Surface unevenness: Moisture infiltration may cause deformation or expansion of the base material of the sandpaper, resulting in an uneven surface of the sandpaper and affecting grinding accuracy.

In order to extend the service life of sandpaper and ensure its excellent performance during use, the following are effective measures to prevent sandpaper from getting damp:

- Proper storage: Stored sandpaper in a dry and ventilated environment, avoiding humid weather or direct contact with water sources. You can consider using sealed bags or desiccants to isolate moisture.

- Avoid high humidity environments: In high humidity environments, sandpaper is prone to moisture absorption, so special care should be taken when storing in high humidity areas to avoid affecting the performance of sandpaper.

- Timely replacement of damaged sandpaper: If the sandpaper is found to have become damp, deformed, or the grinding effect has deteriorated, it should be replaced in a timely manner. To avoid affecting work efficiency and product quality due to the use of substandard sandpaper.